The success of good storage, transport and arrival of table grapes to destination markets depends on a series of factors and circumstances, among which the SO2 generator occupies a prominent, but not the primary, position. Here we analyze some keys and strategies to successfully manage table grapes export programs.

SO2 has been used very successfully for about 100 years to protect table grapes from infection by the fungus Botrytis cinerea Pers. In the early days sulfur was used or charcoal was burned to produce SO2, a practice still observed in Eastern European and Central Asian countries. However, the development of new SO2 application technologies in recent decades has led to substantial improvements in conservation efficiency and results in order to export grapes that maintain their condition and quality, preserving their organoleptic qualities, free of pathogens and attractive to consumers. SO2 is the main tool in the control of Botrytis cinerea because the fungus population can develop even at low storage temperatures (0° Celsius).

This fungal species initiates its development in the field and continues during the post-harvest life of the fruit. As the grape continues its respiratory process after harvest and in particular the stem (rachis) which has a respiratory rate more than 20 times higher than the berry, the antioxidant action of SO2 helps to reduce browning, as it is an inhibitor of oxidative enzymes.

TWO METHODS OF SO2 APPLICATION

Two methods for the application of SO2 to table grapes stand out. The first is the gasification of SO2 in chambers -at ambient temperature- immediately after harvest or in freshly packed grapes, a practice widely used in the United States, Peru and Chile, with variations depending on the reality of each country in terms of infrastructure, logistics and destination markets. In the United States, a new SO2 gasification method called Total Utilization System is being used, which uses the correct doses of SO2, without exceeding them, reducing air pollution and excess sulfite residues.

With the method of application in gasification chambers, spores of Botrytis cinerea and Penicillium present on the surface of the fruit are eliminated. This requires a concentration-time (CT) of 200 ppm/hour of SO2 for Penicillium and 100 ppm/hour for Botrytis, which is sufficient to eliminate more than 90% of the spores. It’s important to note that lethality depends directly on the temperature of the chamber and the fruit, so that at higher temperatures lethality is higher than at low temperatures (close to 0°C). The application of high concentrations of SO2 has a fungicidal action and significantly reduces the inoculum load, which is essential to extend the shelf life of grapes. This method also lowers the respiration rate of the stalks and seals wounds caused during handling of bunches at harvest, which are entry points for fungi.

Generally, in gasification chambers we can observe concentrations between 2,000 and 5,000 ppm, although the doses applied are being reduced to avoid possible damage to the fruit. However, it is necessary to have efficient chambers with adequate designs, since malpractice might lead to increased dehydration of the stalks and potential damage from bleaching, undesirable flavors in the berries and sulfite residues above the norm.

In turn, different varieties have different SO2 absorption capacities, which also depends on their state of maturity, so it is necessary to study this behavior and thus determine the appropriate doses for each variety or group of varieties.

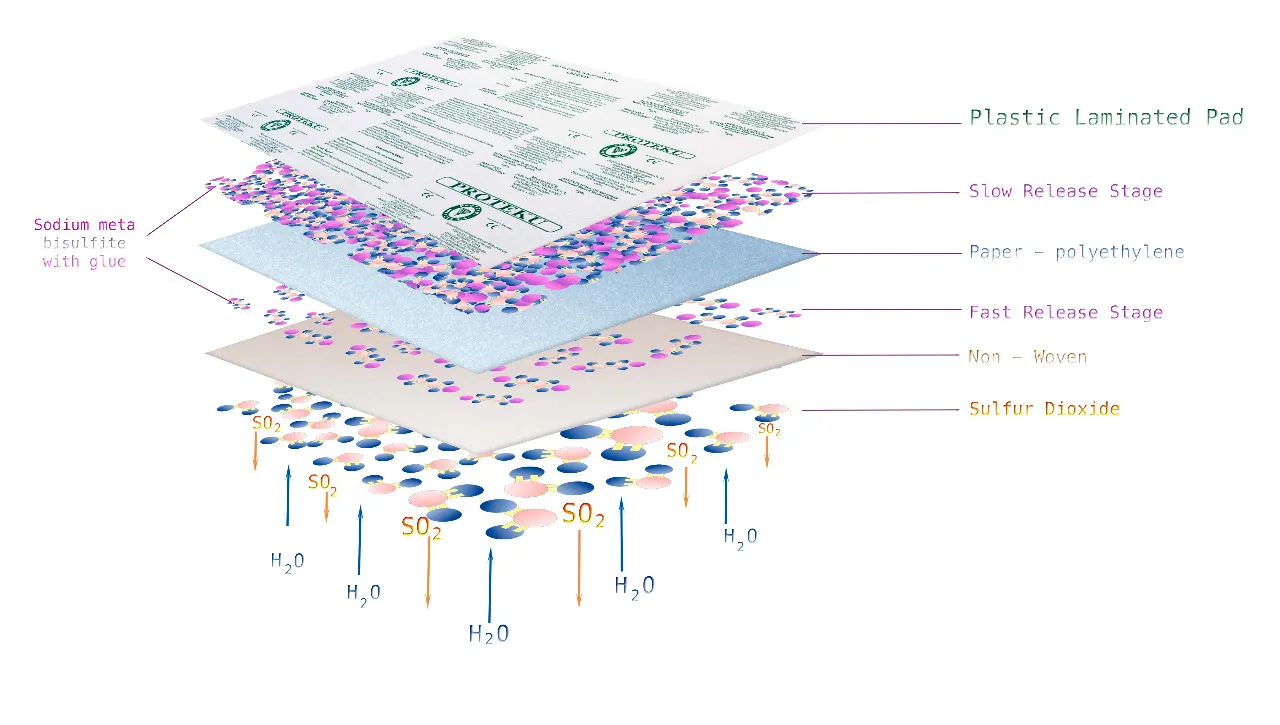

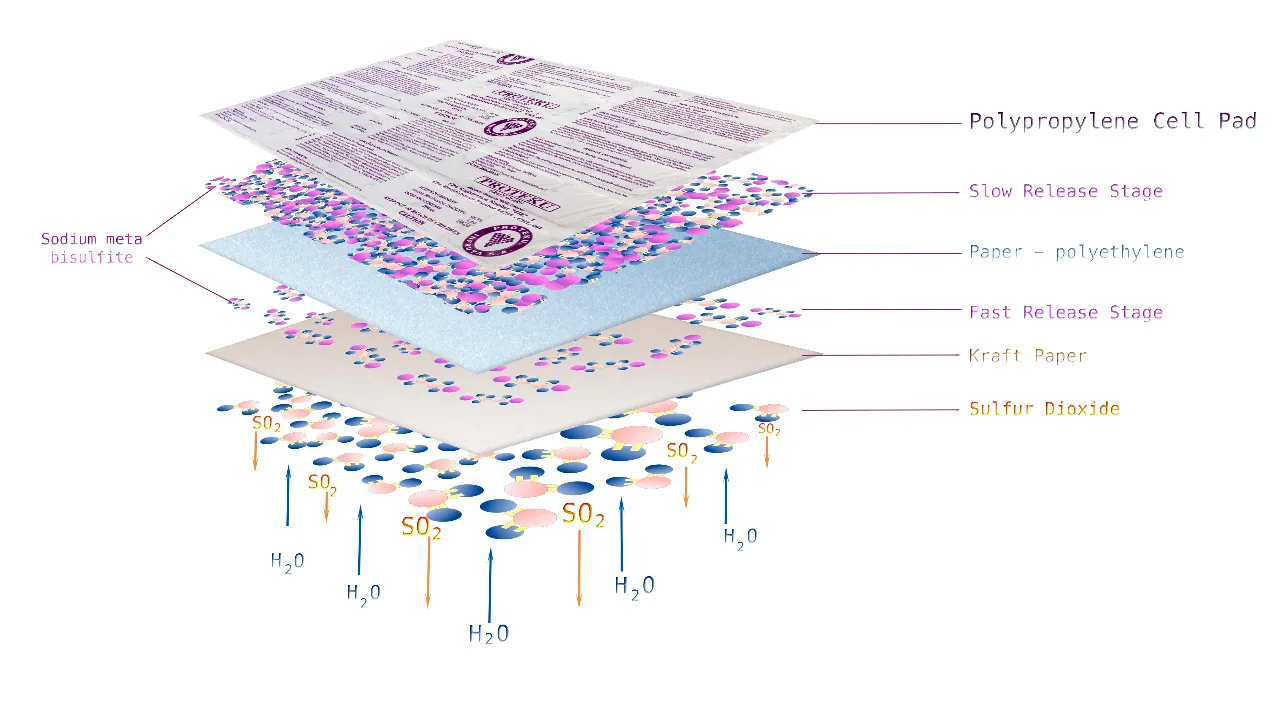

The second method, the use of S02 generating sheets, is the only one used to control Botrytis cinerea in most countries in the world. There are two versions: dual-phase, with a fast and a slow phase, and slow-phase only. To achieve adequate protection, slow-phase generators require fruit to be gassed in a chamber to cover the fast phase. Special SO2 injector machines or SO2 generating devices are also used, which can also efficiently apply an initial gasification.

HOW DO SO2 GENERATORS WORK?

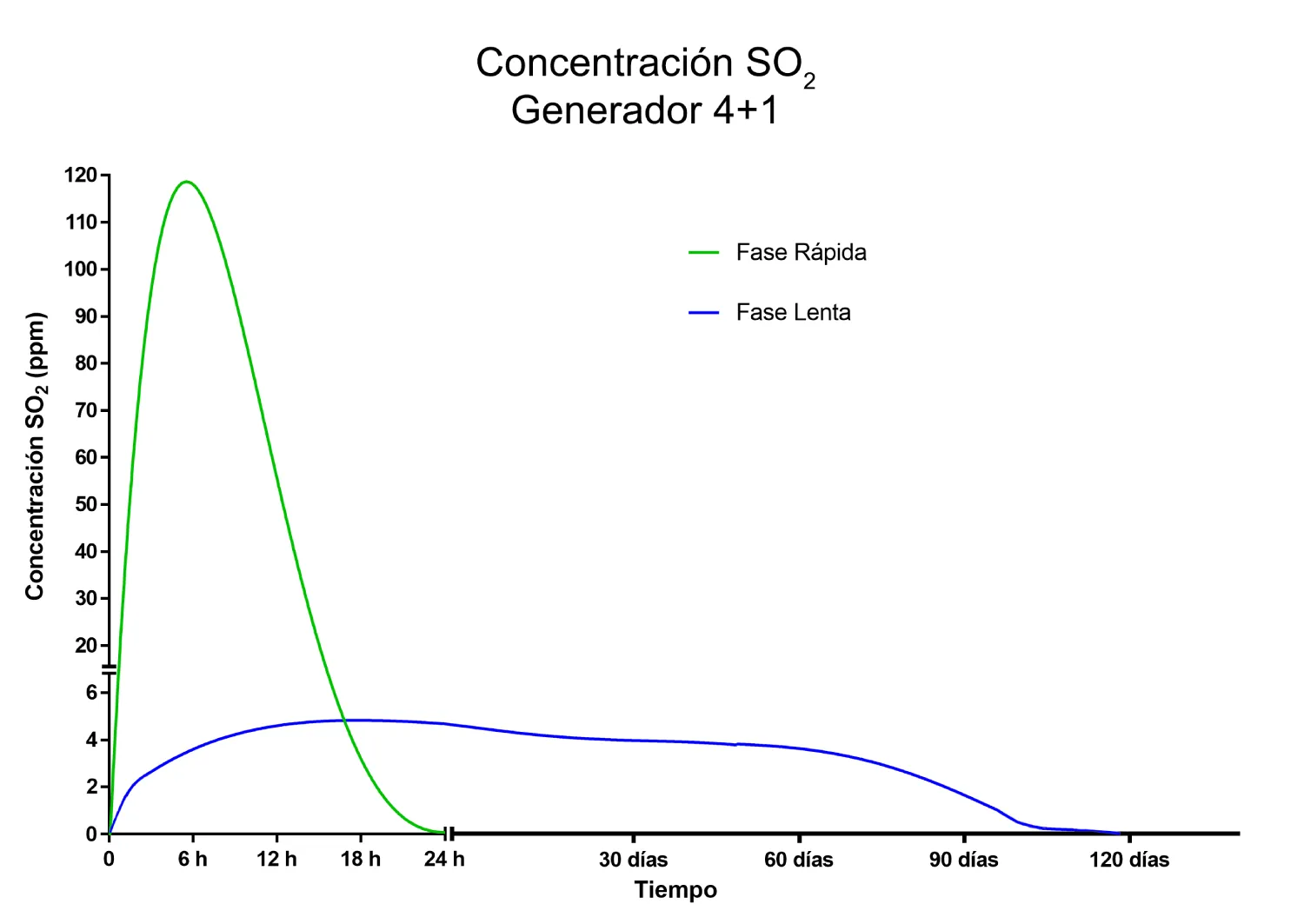

SO2 generators or sheets contain sodium metabisulfite (SM), a salt that reacts chemically with the water vapor coming from the fruit. Once the bag is closed and the relative humidity inside the bag exceeds 70%, the fast phase of the generator begins to act with a fungicidal action. As the environment of the box becomes more humid, the reaction is greater and the emissions also increase exponentially. Without this humid condition inside the boxes, the efficiency of the generators decreases. Typically, the humidity inside a box is above 90% under normal grape packing conditions.

The slow phase begins its fungistatic action or inhibition of the development of Botrytis cinerea spores when the barriers of the polyethylene or polypropylene in the generator are saturated. Depending on storage and transport conditions, the concentrations inside the box reach between 2 and 7 ppm, this dosage also depends on the type of generator. Optimum storage and transport conditions correspond to 0°C and over 90% relative humidity.

To achieve the greatest efficiency of SO2 generators, it is necessary to comply fully with optimal storage and transport conditions, otherwise the device loses effectiveness and the grapes are exposed to post-harvest damage, which can make them unmarketable and unsuitable for consumers.

There are different types of SO2 generators depending on the objective. There are generators with polyethylene paper cells, which emit SO2 on both sides (bidirectional), or polypropylene/polyethylene and plastic laminates, which can be based on polyethylene, polypropylene or polyester. Those that have polypropylene/polyethylene in their structure (cells and/or laminates) are unidirectional and emit SO2 only on the internal side – exposed to the grapes – and due to their own structure are more stable against cold chain breaks, having more controlled emissions, thus preventing the fruit from being subjected to high concentrations that lead to bleaching of the berries, excess sulfites or the grapes being unprotected due to premature exhaustion of the generator.

In the initial stage, called the fast (or first) phase, the dual-phase generators exert a fungicidal action on fungi. Depending on the type of generator, concentrations of between 70 and 130 ppm are achieved and are practically exhausted in the initial cooling of the grapes, with little active ingredient remaining after cooling. Dual-phase generators – with a fast phase – are essential because the alternative ie : chamber gasification leaves a time gap, sometimes several hours, between the process and the packing of the fruit, which under conditions of high Botrytis inoculum pressure, leaves the grapes unprotected and exposed to infection. Without this rapid phase, it is impossible to stop this infection. Therefore, this phase of sanitization is important and can be crucial in certain circumstances for the elimination of surface spores that may be found in the packed box.

The main function of the slow (or second) phase is to inhibit the further development of Botrytis cinerea spores, but it also helps to keep the stalks green and reduce the respiratory rate of the fruit. In this second stage, constant concentrations of between 1.5 and 3 ppm should be achieved around the berries to achieve adequate protection. The generator can be used at the top, but also in botrytis pressure conditions, a bottom second phase only sheet can be added in the bottom of the box, to equate the ppm of gas throughout the whole box.

IS THE AMOUNT OF SODIUM METABISULFITE KEY?

IS THE AMOUNT OF SODIUM METABISULFITE KEY?

The amount of active ingredient, sodium metabisulfite (SM), in a SO2 generator is very important, because it defines the lifespan of the generator and the protection time afforded to the grapes. However, increasing the amount of active ingredient in the generator, in order to increase its shelf life, can be detrimental in the case of a break in the cold chain, as this will result in an excess of SO2 emission from the generator and subsequent damage to the fruit. Therefore, it is essential to use more stable barriers in the manufacture of generators and a correct combination of materials, the most important being polyethylene, polypropylene and polyester.

Suitable combinations of these plastics and quantities of active ingredient in the manufacture of generators avoid overly high and long-lasting emissions over time, during sudden changes in temperature, thus achieving a better protection of the grapes.

Under these manufacturing standards, the unidirectional generators (polypropylene/polyethylene) have a durability of 18 to 19 days per gram of SM in slow phase, while in the case of bidirectional cells (paper/polyethylene) this time can be reduced to 10 to 12 days per gram of SM. With respect to plastic laminates, it is important to specify that when adhesive is used for their manufacture, this acts as an additional barrier, giving this type of generator a shelf life of 20 to 22 days per gram of SM. This shelf life is only achieved when storage and transport conditions are optimal, i.e., 0°C and over 90% relative humidity.

The size of the generator to be used in the different packages is also important. For fruit that between harvest and arrival at destination face periods of more than 3 weeks or for grapes harvested during adverse weather conditions, either rain or fog, it is essential, in addition to the use of bottom pads at the bottom of the box, to use surface generators (top of the box) that cover at least 75% of the internal area of the box, so that the SO2 covers all sides and corners, places where rot usually develops and spreads to the rest of the bunches.

DOUBLE READING OF ABSORBENT MATERIALS

It is also necessary to mention that the absorbent materials used in certain packaging systems have a double reading and different results. Absorbent materials that absorb excess condensation and at the same time protect from direct contact of the generator with the fruit, can also absorb SO2 gas. Because of the hygroscopic nature of SO2, which is strongly attracted to water the gas becomes trapped in the absorbent material itself, although when this material dries out, it becomes a second source of SO2 emission, which is also beneficial.

What is important in the use of these absorbent materials, is to consider the type of liner bag and the ventilation used, the efficiency of the cold and the storage chain and transit times to destination. In general, for short trips and with a good cooling system, with optimum cold storage and transit conditions to destination, it is advisable to use the minimum amount of absorbent material in the boxes.

SO2, as already mentioned, is fundamental, together with good cold management, for the successful preservation and export of grapes. However, it is not exempt from risks due to misuse, since excess concentration inside a box can lead to bleaching, increase micro-cracks when the grapes already show this damage, and can also leave sulfite residues higher than those allowed in the destination countries.

BLEACHING THROUGH TEMPERATURE BREAK

One of the most frequent damages in the preservation of table grapes is bleaching of the berries, caused fundamentally by cold chain breaks which lead to a sharp increase in the emission of SO2 from the generator, increasing the amount of SO2 that the berry is exposed to. The excess of condensation in the boxes in a cold chain break leads to the formation of free water on the berries, and since SO2 is a hydrophilic product, this water attracts a high amount of SO2, which deposits on the berry and causes bleaching.

Grapes, like many other plant organs, have lenticels through which gas exchange with the environment takes place. In the berries these lenticels are covered by a substance called suberin; in turn the berries have a natural wax called pruin, both of which are hydrophobic, acting as a barrier to the environment, preventing the penetration of SO2 into the interior of the berries.

There are 3 basic mechanisms by which berries can be damaged by SO2. The first is when the lenticels are not fully suberized and the bloom coating is incomplete and SO2 manages to penetrate the berry causing localized bleaching. This situation occurs when the grapes have not reached optimum maturity. The second mechanism is when the pedicels are not well attached to the berry or their lenticels are not fully suberized, allowing SO2 to penetrate and causing a halo-like bleaching spreading throughout the rest of the berry. The third mechanism acts through wounds, micro-cracks, bruises and other abrasive damage, causing more irregular bleaching throughout the berry.

STRATEGIES FOR MANAGING TABLE GRAPE EXPORT PROGRAMS

To manage a grape export program, we must define a strategy. Fundamental considerations are the segregation of the product in terms of infection risks, the proper management of SO2, either by gasification or SO2 generators, and efficient cooling and cold chain management.

Three essential aspects need to be considered in SO2 management. The elimination of surface spores on the berries, the concentration of SO2 over time and the use of top and bottom SO2 generators. Nowadays there is a new and crucial tool used massively for certain markets, and conditions, this is the bottom SO2 sheets. These generators are second phase only, and are placed at the bottom of the box in order to cover the SO2 deficiency in the lower third of the box, where SO2 often fails to reach due to the SO2 gradient rate which decreases by half every 2.5 cm of distance of the fruit to the generator.

The bottom pad achieves a more homogeneous concentration in the bottom of the box, which is not achieved by using only the top generator alone. This effect is more noticeable 15 to 20 days after the grapes are packed. The convenience of using bottom pad generators will depend on the storage and transport time, the height of the boxes (necessary in boxes over 10 cm high), the inoculum pressure of each lot, and the environmental conditions before or at the time of harvest (rain or morning mist).

In SO2 management, the ideal is to maintain a uniform concentration in the box between 1.5 and 3 ppm. A concentration of more than 7 ppm for more than 3 days could cause irreversible damage in bleaching, increased micro partitions and sulfite residues higher than 10 ppm in the berries, exceeding the maximum residue levels (MRL) allowed in most countries. In the USA (EPA), as well as in the EC, tolerances and maximum residue limits for sulfites applied to table grapes were established at 10 ppm. Generally, grape consignments are monitored in these destinations to analyze compliance with this important regulation.

When we observe the formation of fungal nests on bunches, especially at destination or even in storage chambers, it is mainly due to a primary infection in the field or a lack of SO2 in postharvest.

In the use of SO2 generators, the performance depends on the amount of active ingredient (sodium metabisulfite), the moisture barriers (polypropylene, polyethylene and polyester) and the ventilation of the boxes and liner bags.

Several factors must be considered that influence fruit condition, such as Botrytis inoculum pressure at harvest, storage time, type and conditions of transport (refrigerated container or ship chamber), but also grape varietal characteristics, including sensitivity to SO2, Botrytis resistance, stem characteristics, as well as berry skin thickness and color.

The correct functioning of the generator will depend on several factors, including temperature, since an increase of temperature during storage or transit leads to a collapse of the SO2 sheet barriers, resulting in high SO2 emissions – with the aforementioned consequences – and a significant shortening of the sheets active lifespan. The high condensation that usually occurs due to poor temperature management or a break in the cold chain also leads to an increase in SO2 emissions.

THE IMPACT OF SO2 IN NEW VARIETIES IN EXPORT MANAGEMENT

In summary, the decision on the type of generator to use, in terms of weight, size, type (cells or laminated), will depend fundamentally on factors such as the storage period and transit to destination; the size of the box and its volume; the grape variety and its sensitivity to SO2; the condition of the grapes at the time of harvest; the potential for fruit rot; the type of harvest (packhouse or field packing) and the possible requirements of certain markets or importers.

The recent incorporation of new table grape varieties has made post-harvest management more difficult. These new varieties have dissimilar post-harvest behaviors, which are still being studied, as well as different post-harvest life depending on different production and climatic conditions.

We have found that some new varieties, when exposed to SO2, behave very differently from traditional varieties. Some of them have shown an extreme sensitivity to SO2, especially the new colored varieties. Additional studies and trials on their behavior are required, in order to define an adequate SO2 management, which will allow them to be marketed without problems in the different markets of the world.

In summary, we can conclude that the success of a good storage, transport and arrival of table grapes at destination, depends on a series of factors and circumstances, among which the SO2 generator occupies a prominent place, but not the primary one.

If the fruit already presents problems and damage caused by pre-harvest, harvest or production issues, combined with inadequate management of the cold chain during storage, transport and arrival at the destination, the SO2 generators will not be able to perform their function optimally. Only through quality work, along the entire value chain, will SO2 generators be able to ensure the control of Botrytis cinerea, resulting in grapes arriving at their destination fresh and healthy, allowing an efficient marketing by importers, as well as a product in optimal conditions and safe for the final consumer.

Ricardo Maldonado

Agronomist Engineer

Commercial Manager

Infruta SA/Proteku